Solid 3.0

Syndet Shampoo Bars.

Industrial process. Transformation.

The development of Solid Cosmetics brought back to the forefront the extrusion of soaps, diversified to the production of solid shampoos.

The process uses extruders whose main step is the shaping. These solid bars, unlike conventional soaps, are not made via saponification of a fat or oil. All these shampoos that use the claim "neutral pH" are syndet bars, that means they are not made with soap.

Indeed, the machine used in this process extrudes in the form of noodles, then in the form of billets before being cut into pieces and pressed to obtain the shampoo bar.

You will discover our know-how in Syndet Shampoo Bars based on extrusion technology. We will also give you some key facts and innovative formulations of shampoo bars by extrusion process.

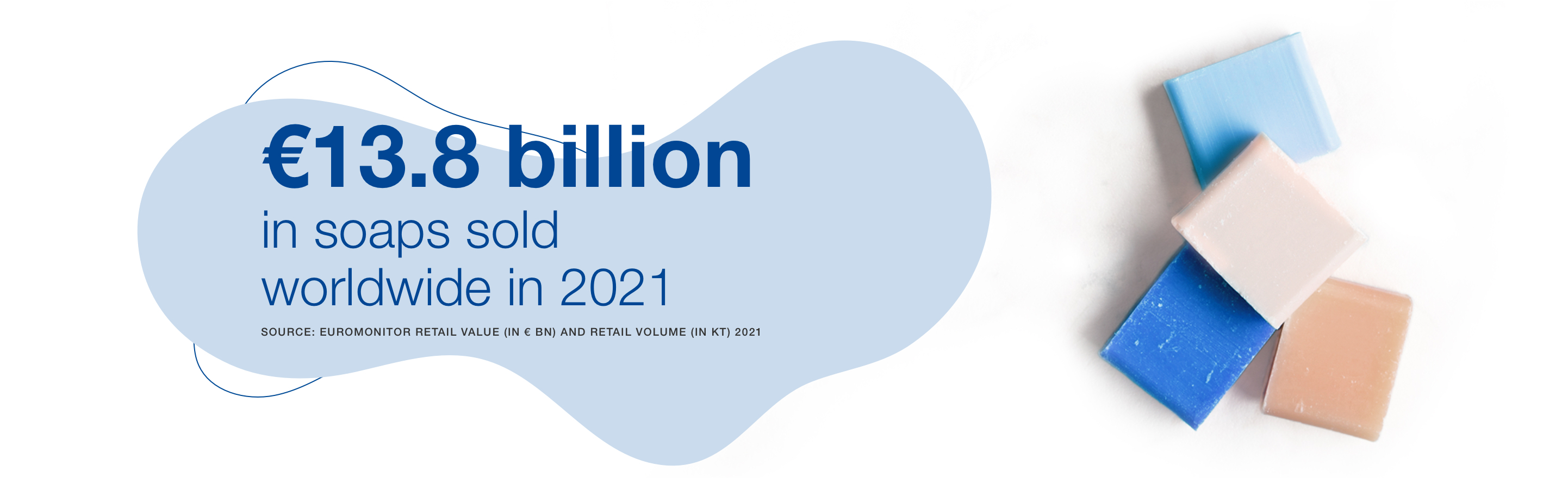

A boom in the Solid Formats’ growth?

Conventional soaps are the oldest and most represented in Solid. They are no longer the only ones to adopt this solid format since the entire bathroom now follows this trend, especially on Shampoo bars.

20%

of Total Skin Cleansing Market Value

3.000

ktons of volumes in 2021

1%

Value 2021-2025 CAGR

Global Market Trend Solid Rinse-off Products

Zero Waste

Reduction of packaging/ waste, Alternative packaging

Ecological Products

Increasing awareness for environmentally friendly products, 100% ecological products

Economics

Economics compared to classical liquid formats

Convenience

Convenience, “on-the-go” product, easy transport

What is the extrusion technology?

Extrusion technology is being taken up in many industries such as Food, Plastic and Pet food and now widely with solid shampoos. It is a mechanical manufacturing process consisting of compressing a material, with heating or cooling, into a given format under the action of pressure.

This process can only be applied to products with a certain consistency or viscosity.

1

Introduction of raw materials. The raw materials are passed through perforated pressure plates via a worm screw: Homogenization of raw materials (Refining).

2

Homogenized noodles fall into a single-screw extruder (3mm and then 5 mm holes) to increase pressure and shape bars.

3

The shaped-bar is then cut and pressed to obtain this oval shape.

4

It remains to put a logo with a stamp for more customization.

What about manufacturing process?

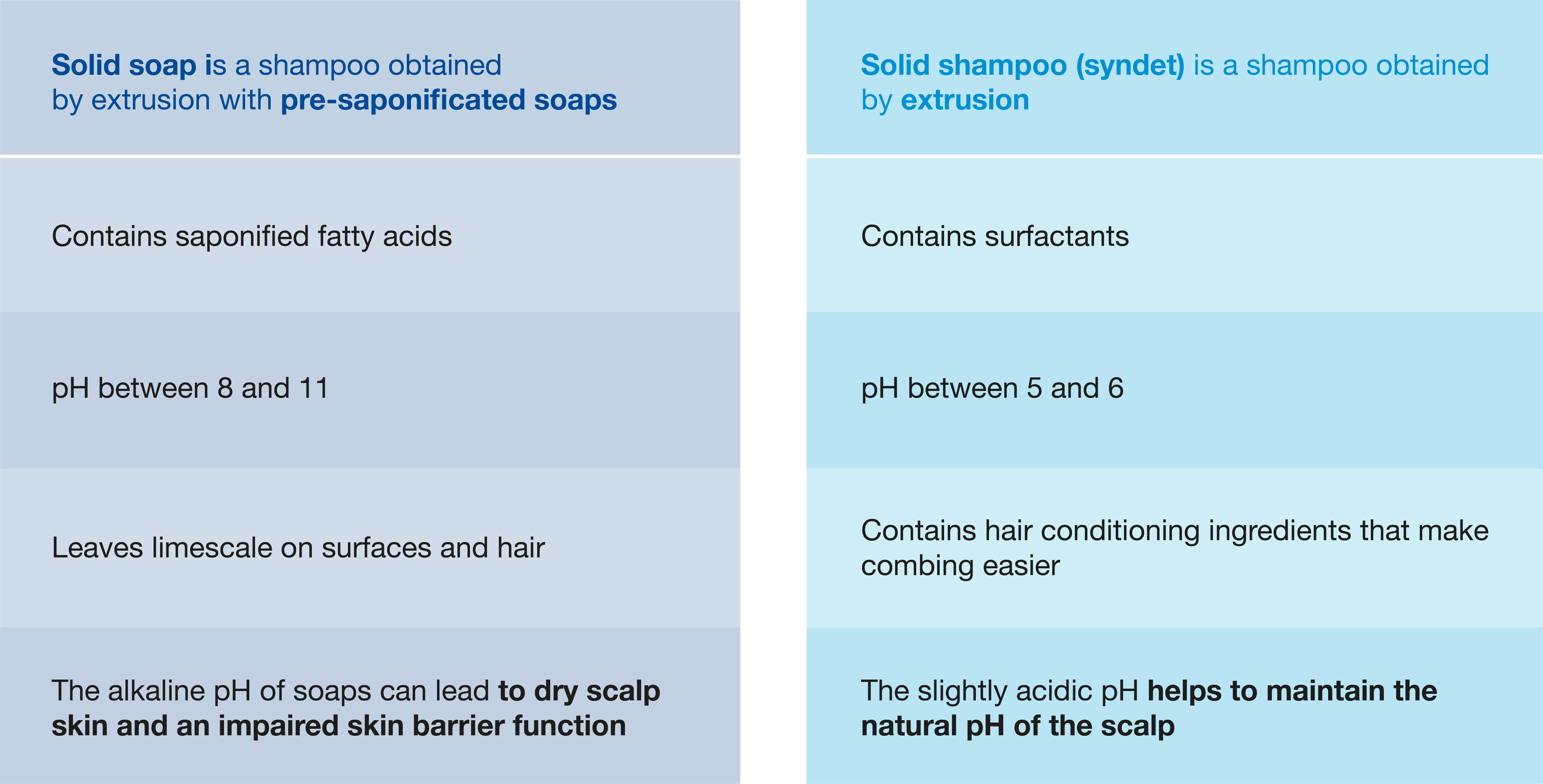

2 ranges of bars share the market with different compositions

Key learnings with the extrusion process?

Meet the extrusion technology for syndet shampoo bars

- Significant hair conditioning boost by Dehyquart® Guar.

- Texapon® SFA UP Powder can be well processed by extrusion, pure and in surfactant blends.

- Moderate addition of liquid APG (~5% active) into shampoo bar formulations can boost flash foaming, mildness and sensory. It leads to nice, well extrudable bars

- Successful extrusion of model recipes with low or high filler content (starch) according to various benchmarks.

- APG shows higher solubility in solid formats than other surfactants.

- APG provides more softness to the bar.

- Maintain a medium temperature during the extrusion process (~40° C) to keep the mixture malleable during the process.

Which ingredients perform?

Anionic and non-ionic surfactants

With or without sulfate, in powder, granule or paste form, they ensure the cleansing of the skin & hair and facilitate the rinsing of anhydrous formulas.

Texapon® SFA UP Powder

Ongoing: Cosmos1 approved

Sulfate surfactant alternative

Jordapon® SCI Powder

Sulfate surfactant alternative

Plantacare® 1200 UP

Cosmos & Natrue approved

Sulfate surfactant alternative

Plantapon® SUS

Sulfate surfactant alternative

Sulfopon® 1216 G

Cosmos & Natrue approved

Consistency agents/ Emollients

Fatty alcohols and fatty acids ensure the stability and hardness of solid products, but also their melting on application.

Lanette® O

Cosmos & Natrue approved

Cegesoft® HF 52

Cosmos & Natrue approved

Cegesoft® HF 62

Cosmos & Natrue approved

Cetiol® SB 45

Cosmos & Natrue approved

Guar Cationic conditioning polymers

Performance and naturalness: our range of conditioners brings softness, detangling and care to the hair products.

Dehyquart® Guar N

Cosmos approved

Dehyquart® Guar HP

Cosmos approved